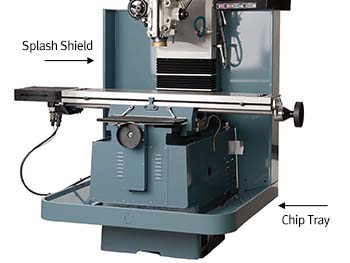

The chip tray and splash shield option is installed at the factory (recommended). The chip tray is installed at the bottom of the machine and the splash shield is installed vertically in front of the electrical cabinet.

A hand-held switch to stop and continue program run.

Huot® ToolScoot cart and preset tool. Tools not included.

Table guard with sliding doors to impede chips and coolant and keep the operator from the tool and workpiece during CNC machining. Interlock switch on the door interfaces to the CNC. DRO and TRAKing are allowed with the door open, but the door must be closed for automatic CNC operations in the Program Run Mode.

Bright, long-lasting LED work lamp with industrial-grade mount.

6″ Kurt vise and mounting hardware - model DX6. Opens to 9″.

The unique Fog Buster® non-fogging coolant sprayer precisely directs a fine stream of coolant to the tool and workpiece.

The feel of manual control of real handwheels, but our electronic handwheels bring the power of the CNC to your fingertips through features such as TRAKing and DO ONE. Standard for TRAK DPM RX5 and TRAK DPM RX7.

A Torque-Rite draw bar factory installed. May be ordered as CAT or NMTB/NST. Draw bar for CAT type is longer to fit into tool holders that have the tool changer grip, or retention knob removed.

A popular brand of glass scale mounted on the table and saddle.

The optional coolant pump is mounted on the back of the machine column. It is wired into the electrical panel for operation through the Accessory key on the CNC front panel.

Switches and brackets are set for maximum travel limits. Tripping the switch will cause the servo motors to shut down.

The USB Memory option consists of an industrial-grade Delkin® Thumb drive. This device is unsurpassed for reliability and speed of file access and is the storage of choice for our own software engineers.

VIDEO: TRAK® USB Memory Option Overview

VIDEO: Installing ProtoTRAK Offline Software

Clear Off allows for the removal of part material from the outside in, leaving only the bosses and profiles you want. This option is easily programmed at the machine, and works with both DXF and Parasolid models.

VIDEO: Clear Off Programming Demo | ProtoTRAK RMX CNC

Write, save and then run programs with RX Canned Cycle Events on Legacy ProtoTRAK controls in either .CAM Events or .GCD format.

VIDEO: Installing ProtoTRAK Offline Software

The TRAK MTConnect option enables customers to add MTConnect functionality quickly and easily to their machines, so that machine data can be collected using the standard MTConnect protocol.

3rd party software not included.

VIDEO: MTConnect® Option Overview

Enables programming and control of coolant, air (for Fog Buster® or other air-driven coolant systems), pulse Indexer and programable output signal.